Qingdao LEWIS Petrochemical Co., Ltd.

About Us

Qingdao LEWIS Petrochemical Co., Ltd., located in the city of brands—Qingdao, is an authorized enterprise of the American LEWIS International Petroleum Group in China. LEWIS is an international energy company with strong technical competitiveness. To further accelerate its strategic expansion in the Asian market, LEWIS has invested in building the LEWIS China Factory in Qingdao. By leveraging leading international technology and advanced management models, and fully utilizing Qingdao’s port transportation advantages, the company establishes its base in Qingdao to radiate across Asian, Africa and the Middle East market.

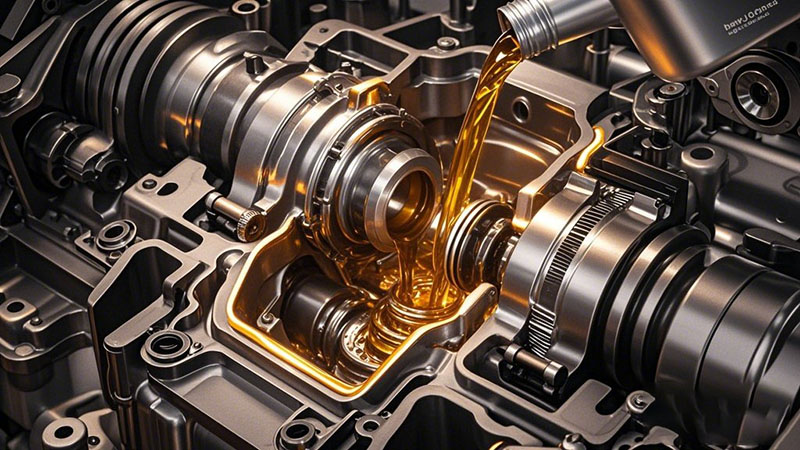

The LEWIS China Factory is located within the Jimo Environmental Protection Industrial Park in Qingdao City, introducing the American RCS remote production control system. From the central control room, the system manages the base oil, blending kettles, and finished product tanks remotely. The digital production management system ensures the standardization and normalization of production processes, effectively guaranteeing product consistency. Among these, the base oil storage area employs digital self-control management, the blending process uses microgram weighing-style pulse blending, and the finished product tank area adopts remote intelligent management. LEWIS lubricants all use imported raw materials, selecting high-quality imported base oils from Formosa Plastics, GS, Sinopec, Shell, and Mobil, and high-quality imported additives from Afton, Chevron, and Rian Chemicals. High-quality raw materials and strict production process control ensure excellent product specifications and maintain long-lasting stability.

LEWIS products meet the specifications of well-known automobile and engine manufacturers like Mercedes-Benz, Volkswagen, Volvo, and Cummins. LEWIS products comply with standards of international lubricant organizations and automotive organizations such as theAPI (American Petroleum Institute), SAE (Society of Automotive Engineers), and ACEA (European Automobile Manufacturers’ Association).

Product technological innovation is an eternal pursuit of LEWIS. Based on various road and vehicle conditions in different countries, LEWIS continuously introduces lubricant products that better meet market demands. “Eco Automotive Oil” uses “Active Factor Cleaning Technology,” specially developed to clean and protect engines. It can effectively prevent the formation of carbon deposits and sludge, extend engine life, and make driving smoother. “Max Diesel Oil” adopts a “high alkalinity low phosphorus” formula, with stable oil pressure, low wear, strong power, a longer oil change interval, and reduced operational costs for commercial vehicles.

Adhering to the mission of “Drive Performance Beyond Limits” and the vision of “Innovative Lubrication for a Sustainable Future “, LEWIS provides high-quality products and services to the Chinese lubricant market. With quality at the core and the market as the guide, LEWIS continuously innovates technology, enhances the overall strength of the brand, and builds a more competitive lubricant brand.

Company Advantages

Microgram Weighing Automatic Feed Control System

Each reconcile kettle's column base is equipped with a load sensor to monitor the weight of components within the kettle. The data is transmitted to the control system via Profibus-DP communication. Once the control system receives real-time weight parameters, it implements program-linked control through a computer workstation, automatically controlling the feed pump, the discharge valve of the base oil tank, and the feed valve of the reconcile kettle. This ensures precise batching according to the programmed formula.

The program controls pipeline diversion to ensure oils do not mix

Using the ET200 series/ O controller, the blended and tested oil is transferred to the corresponding semi-finished product tank. The oil is diverted through an electromagnetic pneumatic valve and transferred to the semi-finished product tank after passing through a bag filter. The liquid level of each oil type can be monitored through level sensors installed on the semi-finished product tanks to track inventory levels. If the liquid level in the semi-finished product tank exceeds the warning line, the system will issue an alarm and automatically stop the pump.

ACTIVE FACTOR LUBRICATION CLEANING TECHNOLOGY

ECHO Engine Oil utilizes 'Active Factor Cleaning Technology', specifically developed to clean and protect engines. It effectively prevents the formation of carbon deposits and sludge, extending engine life and ensuring smoother driving. Ordinary lubricants cannot prevent dirt particles from clumping together to form sludge and adhering to the engine surface, which can cause the lubricant to malfunction and lead to premature engine failure. LEWIS Active Dispersant Factors effectively prevent dirt particles from clumping together and forming sludge.